Enzymes for biodiesel

Feedstock flexibility for your plant

Enzymes for biodiesel

Process a range of Free Fatty Acid (FFA) feedstocks

The biodiesel market is currently dominated by conventional oils like soybean, rapeseed and palm oil. What if you had the flexibility to lower your raw material costs by using alternative feedstocks? With Eversa® Transform, our enzymatic solution for biodiesel, you can process the entire range of FFA feedstocks.

Adapt to changing biodiesel markets

Adapt to changing biodiesel markets

Eversa® Transform allows you to always switch to the lowest-cost feedstock. These include secondary oils like fatty acid distillates and distillers' grain solubles (DGS) corn oil. They also include Used Cooking Oil (UCO) and animal fats. By giving you the freedom to choose, Eversa® Transform helps you lower your raw material costs. It also minimizes your dependence on conventional feedstocks.

Meet the growing mandated demand for biodiesel

Meet the growing mandated demand for biodiesel

In every region of the world, governments are mandating the use of new and higher biodiesel blends. Examples include the B30 in Indonesia and the B13 in Brazil. Other examples are the European Renewable Energy Directive (RED II) and the LCSF in California. All these policies will create more demand for the biodiesel you produce.

Get higher quality glycerin

Get higher quality glycerin

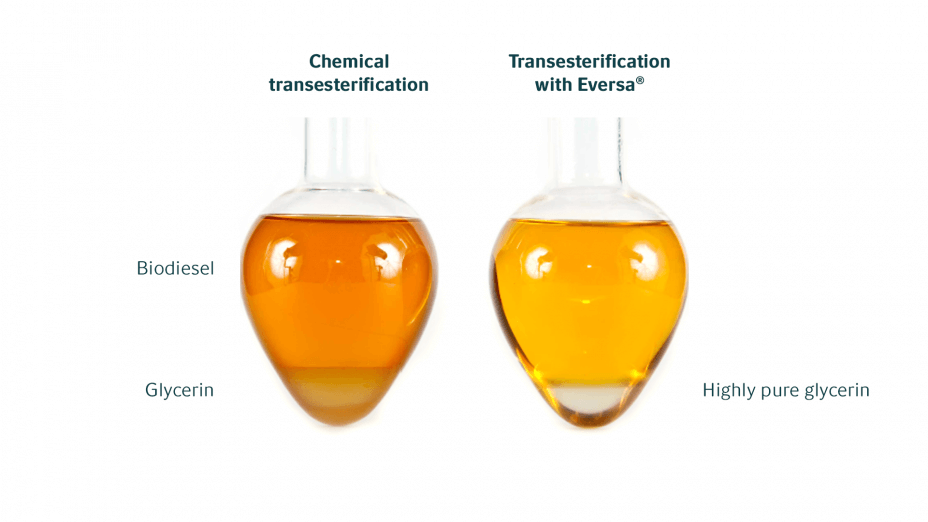

The enzymatic biodiesel process with Eversa® Transform generates highly-pure, salt- and soap-free glycerin.

The absence of by-products makes it much simpler for you to generate technical-grade glycerin. All it takes is simple evaporation.