Less Corn,

Less Energy,

More Profit.

Less Corn,

Less Energy,

More Profit.

Your current

production limits are

holding you back

Your current

production limits are

holding you back

As a corn wet miller, you know that

fluctuating starch demand is a challenge to a fixed equipment base: if starch production goes down, your fixed cost per unit of starch will increase, and this will eat up your margin and make your mill less competitive.

After more than a century of mechanical process improvements, there's a limit to how more efficiency can be squeezed out of the mill. Simply cutting costs has diminishing returns.

Separation Efficiency

What if you could take separation efficiency beyond the limits of today?

To strengthen your business and improve your margins, you focus on how process improvements can break through conventional limits on yields and operational costs.

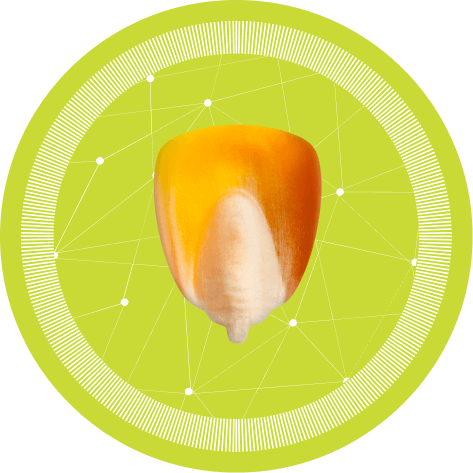

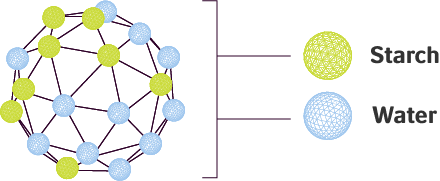

When you add enzymatic separation to mechanical separation, you improve the process to release more starch and water. With it, you release trapped operational flexibility, which helps meet your fluctuating starch demand with less equipment, less corn, less utilities, and in less time.

Frontia® Fiberwash the Technology that

Allows You to Get the Most Out of Your Corn

Adding enzymes to your existing wet milling

process, will allow you to squeeze more from

your corn. Frontia® enzymatic corn separation

starts where mechanical separation stops.

Frontia® users get the

most from their

corn and their mills

Frontia® users get the

most from their

corn and their mills

To get the most value, you need to give

Frontia time to work by adding an

incubation step.

On average, we’ve seen more than

50 % of plants have retrofitted

using existing equipment.

Novozymes is with you every step of the way

| Proven three step implementation process to ensure risk mitigation |

| Years of Industry Expertise Across | |

| Countries |

Our Technical Service Team

comprised of wet milling experts

speak to over 200 mills globally

Join the Enzymatic Corn

Wet Mill Revolution

Get the most from your

corn and all your mills

+2%

Additional starch yield means less corn for the same output

-15-20%

Less co-product drying energy

$2.7M

Annual savings (for a 160,000 bushels corn/day facility)